Natural resource scarcity impacts supply chains and the way forward

Posted on 23rd November 2021 at 13:59

Supply Chain shortages – it’s not just the drivers!

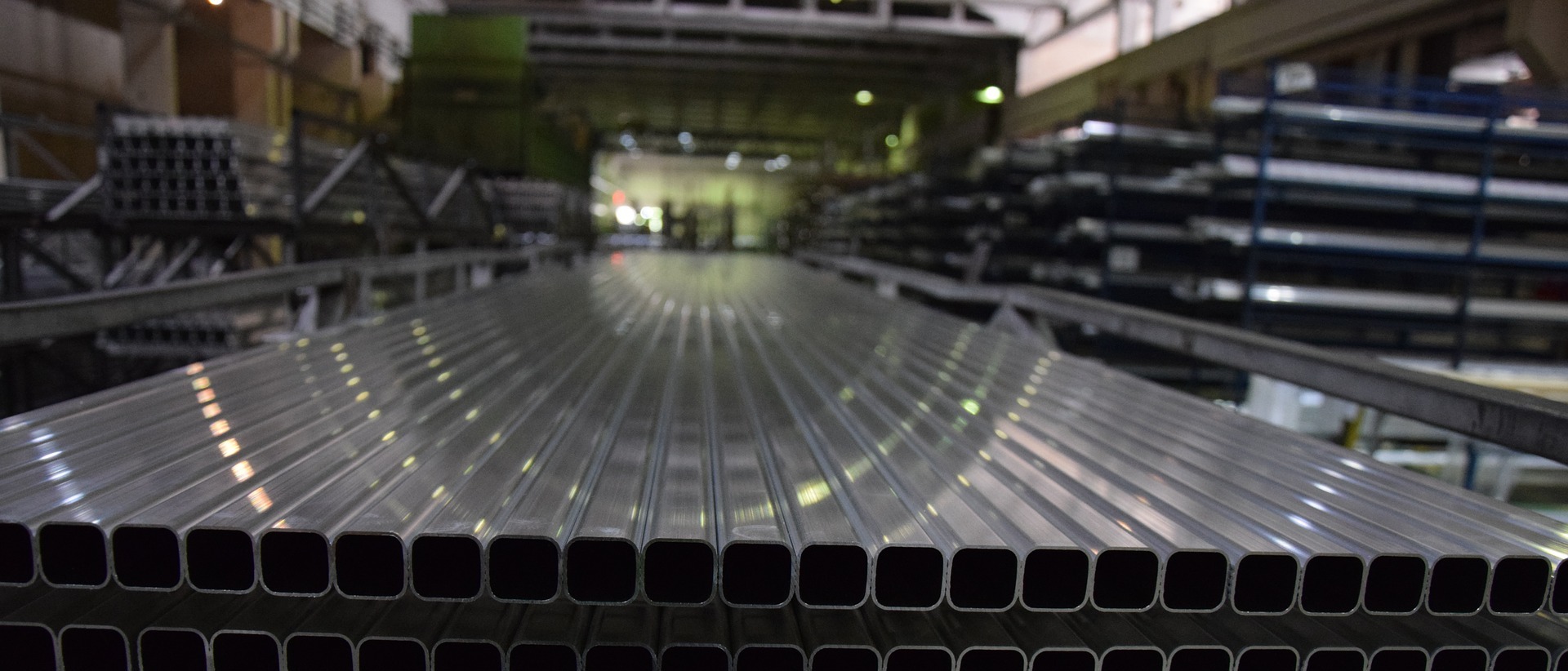

It’s also the magic of magnesium. Supply Chains make the world go around. But supply chains are even more precious than we thought. Magnesium makes metals lightweight – which is vital for successful supply chains and manufacturing. Without magnesium we don’t have aluminium and without aluminium we don’t have cars, or lightweight metal packaging for medicines, and much, much more. But we are dependent on other countries - especially China - for these precious elements. Diversifying the sources of supply and introducing substitutes for precious elements will make our supply chains and manufacturing less dependent, more resilient and more successful.

Over the past 200 years, resource scarcity has been considered as a challenging topic disrupting several countries and manufacturing supply chains. As Kalaitzi et al. (2018) have highlighted the degree of dependency on scarce natural resources stems from three contingent factors: Firstly, the importance (price, quantity, and functional criticality); secondly, supplier substitutability (the availability of alternative suppliers and the relevant switching costs), and lastly the discretion over the resource (ownership).

For example, China has a monopoly on rare earth metals and can control the availability of these resources; thus, making vulnerable manufacturing companies and countries such as the UK and USA that are dependent on these natural resources. Moreover, recently China closed several magnesium smelters to handle its energy crisis which is causing global shortages of magnesium. It is expected that this would lead to shortages of aluminium at the end of 2021 which will have severe impacts on the automotive industry (Rowsell, 2011). Another recent example is the soaring natural gas prices that led to shortage of nitrogen fertilizer. Companies have no options available but to reduce production. For example, a US manufacturer of agricultural fertilisers stopped operations in the UK, and countries such as Russia and China are also limiting nitrogen exports. So, what next?

Companies have to start plotting a way forward and set strategies for managing resource dependencies in the supply chain. Strategies that could be utilised include (Kalaitzi et al., 2018):

product and processes (re)configuration;

supply chain (re)configuration;

transactional mechanisms;

relational mechanisms, and

vertical integration.

Different contingent factors such as discretion over the resources in terms of legislation affect the appropriateness of various strategies. For example, product and processes (re)configuration strategies are used as a defense strategy to overcome the resource dependence and minimise the purchasing cost. Supply chain diversification can also support and enable the accessibility to those resources, as Einhorn the CEO of Dealmed (medical supply distributor company) stated that supply chains depend too much on products sourced from China. For example, producing rare earths in multiple countries (e.g., Canada) could make the supply chain more stable.

Moreover, circular economy and recycling could be an ethical source of scarce natural resources in the future. For example, Tesla is preparing to process waste batteries and building recycling capabilities at its Gigafactory in Nevada. Overall, these strategies can have a positive impact on organisational performance. Kalaitzi et al. (2019) found that close collaboration and partnerships can help companies to share knowledge of raw materials for their production and co-location. Thus, a positive impact on resource efficiency and competitive advantage in times of natural resource scarcity. However, some of these strategies, such as investing in new technologies or plant relocations, are costly and can lead to a competitive disadvantage particularly for SMEs. Thus, governments need to provide incentives and support companies to implement emerging technologies and improve the usage of scarce natural resources.

Dimitra Kalaitzi is an early career researcher, and her main research area is on supply chain (re-) configuration and product (re-) configuration in order to handle the issue of natural resource scarcity/sustainability and achieve resource efficiency.

To find out more about how UK-Centric Supply Chains can help your business, why not get in contact with us today?

References:

Kalaitzi, D., Matopoulos, A., Bourlakis, M. & Tate, W. L., (2018), Supply chain strategies in an era of natural resource scarcity. International Journal of Operations and Production Management. 38, 3, p. 784-809

Kalaitzi, D., Matopoulos, A., Bourlakis, M. & Tate, W., (2019), Supply chains under resource pressure: Strategies for improving resource efficiency and competitive advantage. International Journal of Operations and Production Management. 39, 12, p. 1323-1354

Nickel, R. (2021). Nitrogen fertilizer shortage threatens to cut global crop yields -CF Industries, available at: https://www.reuters.com/business/energy/nitrogen-fertilizer-shortage-threatens-cut-global-crop-yields-cf-industries-2021-11-04/, (accessed 10/11/2021).

Rowsell, J. (2021) . Fears for aluminium supply as magnesium shortage bites, available at: https://www.cips.org/supply-management/news/2021/november/fears-for-aluminium-supply-as-magnesium-shortage-bites/, (accessed 10/11/2021).

Tagged as: Natural resource scarcity, Resource depletion

Share this post: