What is the right Supply Chain for your Product?

Posted on 2nd October 2022 at 14:26

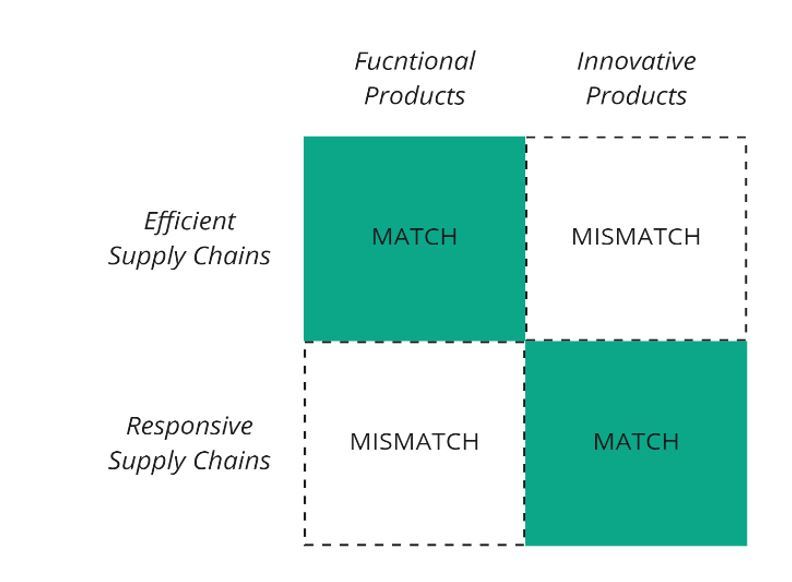

This is the name of Marshall L. Fisher's (1997) seminal work. The key message is simple: “Before devising a supply chain consider the nature of your products”, meaning matching the right Supply Chain with the right Product. He proposed a framework where products are either functional (predictable demand) or innovative (unpredictable demand), and supply chains physically efficient (lean supply chain) or market-responsive (agile supply chain).

After 25 years, even though many studies confirmed the importance of aligning product and supply chain, the alignment failures are countless.

If there is one sector that should have gotten this right by now is the Automotive Industry. After all, it is a sector recognised for its efficiency to manage complex structures and innovation in launching new products. Unfortunately, the reality shows a quite different story:

Supply Chain disruptions are a regular in today’s news and are expected to stay in the spotlight for a while (Reuters, 2022). No one expects that companies should avoid pandemics, earthquakes, or global raw material shortages, but they should reflect on their Supply Chain when designing their products.

Through the years, a variety of methods were proposed addressing the supply chain alignment problem. For instance, Van Hoek and Chapman (2007) proposed a three-step process to improve the Supply Chain-Product alignment.

Step 1: Improve basic alignment, by improving communication and training in supply chain management but also cultivating the planning process.

Step 2: Improving Supply Chain Readiness, to execute with fewer issues and without much firefighting.

Step 3: Leveraging Supply Chain Capability, with Suppliers helping drive revenue growth, moving beyond collaboration into true joint missions.

At UK-Centric Supply Chains, we have the capabilities to assist you in this journey, so your Company can fulfil Fisher’s 25-year calling of devising the right Supply Chain for your Product. You can start by undertaking our Instant Supply Chain Health Check.

References:

Fisher, M. (1997) ‘What is the right supply chain for your product?’, Harvard business review, pp. 105–116.

Van Hoek, R. and Chapman, P. (2007) ‘How to move supply chain beyond cleaning up after new product development’, Supply Chain Management: An International Journal, 12(4), pp. 239–244.

Filipe Sarmento is a PhD candidate in Engineering Systems & Supply Chain Management at Aston University. He researches about the impact of Supply Chain design in New Product Development programmes. His aim is to help shift the awareness of organisations into a more Supply Chain-centric World.

To find out more about how UK-Centric Supply Chains can help your business, why not get in contact with us today?

Share this post: